How Much Do You Know about Cold Forging?

According to the temperature at which it is executed, forging is classified in "", "" as well as "". The makers used to press and deform the material into high stamina components can be split in the following classifications: Pressure building makers with rotational movements: longitudinal as well as radial rolling mills Combination of pressure devices with translational and also rotational activities: orbital forging as well as flospinning It is necessary to keep in mind that the building manufacturing process is totally different from the one, where the molten material is poured into a mold and mildew.

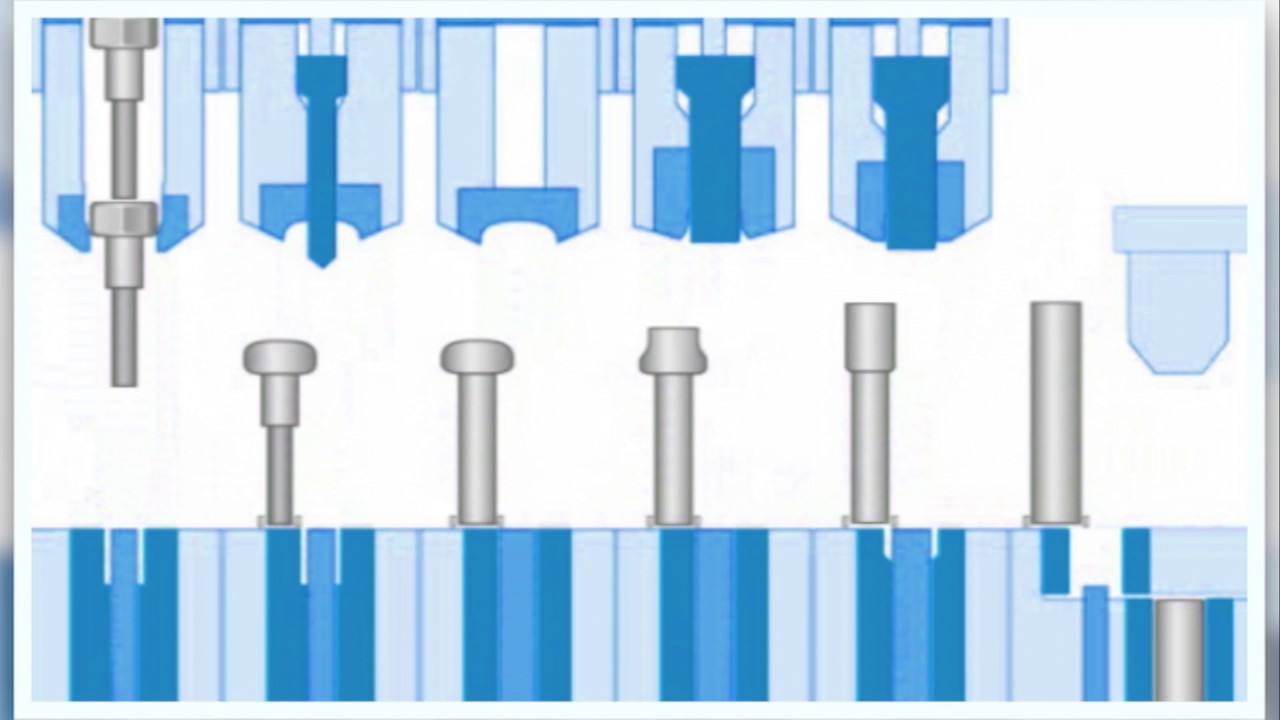

The cool forging production process is executed at area temperature (cold forging). The workpiece is pressed in between 2 dies till it has actually thought their form. To supply a finished, prepared to fit part, the technique includes rolling, drawing, pushing, rotating, squeezing out and also heading. Cold creating extrusion is among one of the most usual production strategies, commonly utilized in the production of elements.

Considering that all bars are annealed before being created, there is no demand for a secondary warm treatment before machining. Another substantial advantage is the product financial savings achieved via near internet forms. The initial weight of the work surface equals the final weight of the cool built part. Cold forged components supply a good level of obtainable dimensional accuracy as well as exceptional surface quality - cold forging.

Depending upon the producer's requirements, several of the cool forging features might end up downsides; e. g. just simple forms in high quantities can be formed. The possible deformation degrees and forming quality are a lot more minimal compared to marking. As a result, if the consumer is browsing for a specific customized element, cold forging won't be the most effective choice (cold forging).

Also, as a result of the grain framework that offers the product its toughness, recurring stress and anxiety may take place (cold forging). It is necessary to mention that chilly forging extrusion for instance requires additionally a warm therapy to get rid of feasible fractures, creeks solidifying or rafters. As a consequence of the above statements, cold creating can not be utilized on every steel quality, especially on those with low ductility or level of sensitivity to strain hardening.

评论

发表评论